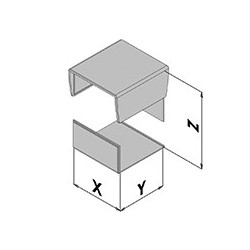

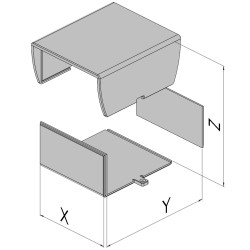

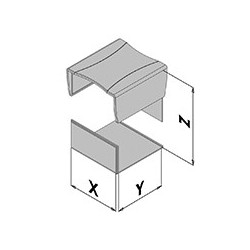

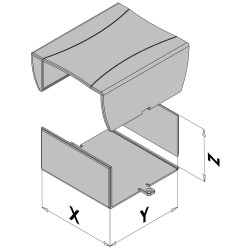

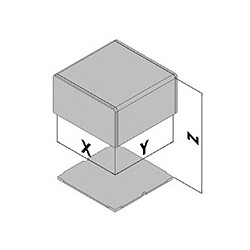

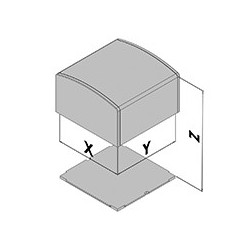

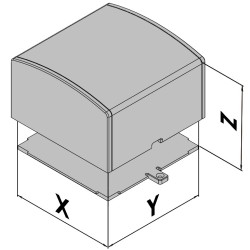

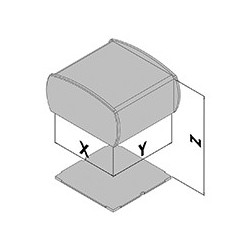

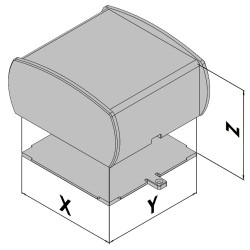

Model : EC10-100-0

Quotation online 24/7

5 to 10 workings days

Quotation online 24/7

5 to 10 workings days

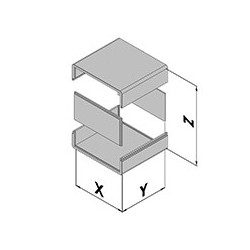

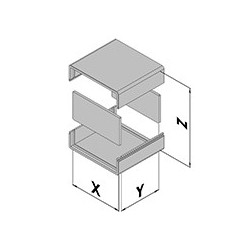

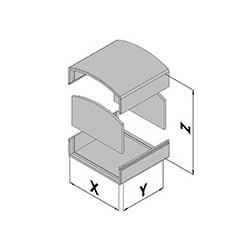

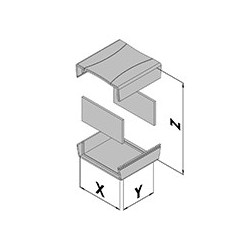

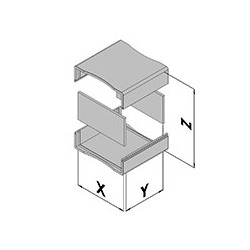

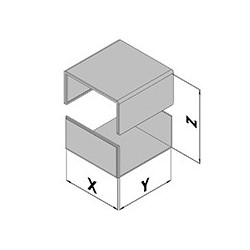

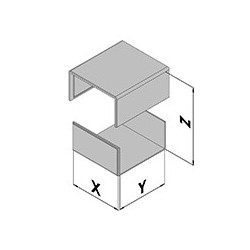

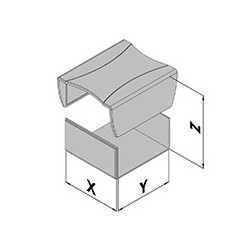

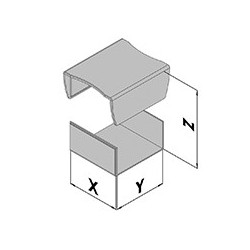

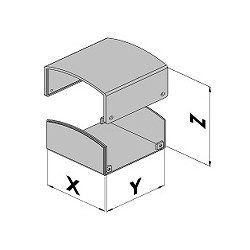

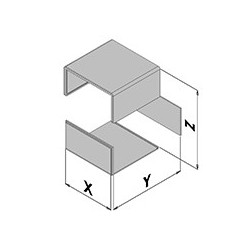

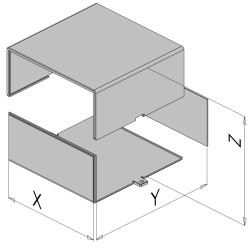

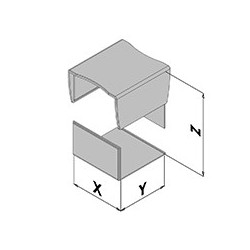

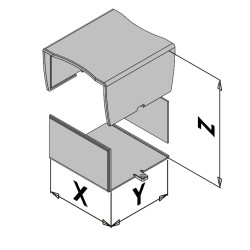

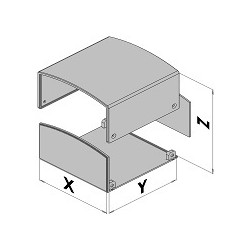

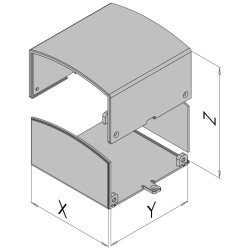

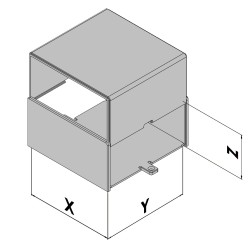

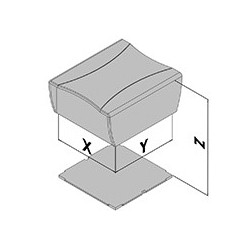

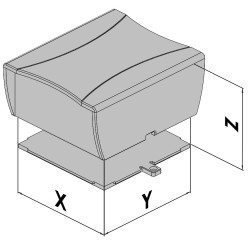

Custom plastic enclosure consisting of Two U; or C;-shaped pieces, snap together with tongue and groove. 2 panels snapped in a groove.

Develop a custom designed desktop enclosure, housing, sloped enclosure or kiosk – trolley enclosure with the local LTP representative in your country !

| Choice of the pre-designed enclosure construction (i.e. EC10-200-0) or an enclosure 100% custom designed. |

| Filling in the quote form online and create an online account on the first request. | |

| Automatic receipt of a quote by email and in the account (Prototype price and Serial price based on the order quantity) | |

| Our Quoting team will contact you in order to approve your instant quote. | |

| Your approved quote will then be saved in "My account". | |

| Order your prototype online or by email based on the validated online instant quote. | |

| Programming and production of a custom designed prototype enclosure including all requested finishing and mounting features. | |

| Order your serial production based on the prototype tested and validated. |

How to choose the suitable pre-designed ElectroniCase model ?

Configuration & Quotation directly online 24/7.

Based on one of the over 50 pre-designed enclosure constructions, represented through a 3D CAD-drawing online.

Make the right decision, when it comes to choosing a suitable pre-designed model for the development of a bespoke custom designed enclosure, front panel, cover or housing for an electronic device.

How to choose the suitable pre-designed ElectroniCase model ?

Configuration & Quotation directly online 24/7.

Based on one of the over 50 pre-designed enclosure constructions, represented through a 3D CAD-drawing online.

Make the right decision, when it comes to choosing a suitable pre-designed model for the development of a bespoke custom designed enclosure, front panel, cover or housing for an electronic device.

None of the pre-designed models suits you ?

With LTP's local partner, specialised in enclosure R&D.

The shape and construction design are 100% custom designed, based on your specifications.

The enclosure will be developed according to the required space of the electronic equipment, the application environment and use.

The enclosure design will be proposed by the LTP technicians.

ElectroniCase is a brand of LTP. It is a range of pre – designed enclosures, which can be configured as per your specifications. The range ElectroniCase is based on the LTP technology, which has been invented for this purpose: designing and manufacturing customised enclosure WITHOUT ANY TOOLING costs. Once you have chosen the right model within the ElectroniCase range, you can configure it entirely as per your needs (dimensions, milling, finishing, internal fixtures, etc.); Like this a « standard » model becomes unique and entirely customised.

Our product designs have been worked out to keep production costs at lowest. Furthermore, we are present in over 7 countries via this webpage, accessible to anybody, which means, that with this positioning, we are currently faced to permanent competition.

Because you have in just 1 step a totally customised enclosure, no need to rework, which is still very economic, quick and simple.

No, with ElectroniCase, you will receive an enclosure ready to be used and entirely finalized. There will be no need to re-mill or embellish.

1 single supplier for your enclosure

During the product design, we will adapt ourselves to your PCB, your components and their implementation: You will not have to rework or adapt your electronic elements. Before starting the production of the prototype, our team can send you a 3D to validate the drawing. You can also send us your parts. The prototype will allow you to check the mounting of your components in the enclosure.

Yes, this is a juxtaposition of two words in the form of an oxymoron. De facto, those 2 words cover the reality: We start with a standard model, for which the product design exists. This model is then configured, adapted to your dimensions and finishing becoming after this work “customised”.

Standard concerns the product designs. We have worked out various product designs, that cover the most current utilisation needs. You must choose amongst those models.

Standard stands for the product design; Customised stands for the rest: the dimensions, the cut outs, the fixtures, the marking and the paint.

Only the model type (production design / shape) will be defined. It is up to you, to make your choice within a large database of “standard” ElectroniCase models. After this point the enclosure becomes “customised”, as you define your dimensions, your cut outs, your internal fixtures, your marking (logo/instructions) and your painting (optional).

The price depends on the project and requested finishing. The price is situated approximately between 195€ and 800€.

Our technology is adapted to small and medium size serial production runs and efficient from ten to thousands of parts. The drop over point to the injection moulding technology, depends on the type of the product and the anticipation of the product stabilization without any modifications.

If your enclosure faces a market with big series of several thousands of parts, our LTP-Multitechnology-Team, specialised in sub-contracting will take over and propose a transfer to the adapted technology at that point in time (most probably injection).

Our technology for small and medium size production runs is efficient from a dozen up to several thousand. The breaking point with the injection technology depends upon the type of the product and the anticipation of the product stability without modification.

If your enclosure faces a market with big series of several thousands of parts, our LTP-Multitechnology-Team, specialised in sub-contracting will take over and propose a transfer to the adapted technology at that point in time (most probably injection).

Yes the prototype is compulsory to validate the product design. It is also the contractual reference for the serial production.

The product design of an enclosure or housing, will be materialised via 2 steps:

The choice of the product design, depends upon the mounting method of your components and the use.

You can independently choose on our webpage or ask our service team for help: The button « contact » can be found on each page.

Based on your needs, which only you know or sketches should allow you to make your choice. If you do have a question our service team would be delighted to help. The button « contact » can be found on each page.

Once the actual product design will have been chosen, the model type is only down to taste and aesthetic criteria, which are up to you.

You can order the enclosure based on the approved instant quote. In the step after approval you can decide to place the order either directly online or via our service team.

Link: How it works? How to order

We have conducted a detailed study which you can find on the following link: Advantages

Do not hesitate to contact our service team, who will give you advice and accompany you in the decision process. The button « contact » can be found on each page.

Yes, we do have an internal designer, who has designed the models of the ElectroniCase product range including the basic models but also the additional once with decorative grooves, overlapping edges etc. If none of those models suites you, we can design one for you.

For a « standard to be configured » enclosure, you can choose among a wide selection in our ElectroniCase product range.

Yes, but only within the LTP offer and within the feasibility of the technology "Tôlerie Plastique".

The button « contact LTP » is available on each page.

The available raw materials are: White or black ABS and black polycarbonate.

The windows are made of transparent PMMA.

Yes, we have self-extinguishing PS choc classified ULV0 available.

We recycle a big majority of the plastic sheet waste. Like this we contribute towards the optimisation of the plastic raw material life cycle.

As specified on the web page under « Delivery Time » the lead time is 5 day working days, commencing upon receipt of all necessary technical information for your enclosure without any finishing. To this lead time you must add days, if we need to mount components, for print and for varnish. A lead time can go up to 16 working days, starting from the day, we will have received complete information.

After the validation of the prototype, the lead time for ElectroniCase product range is standard: 3 weeks

Yes, they are. Our organisation and procedures have been put in place to ensure this reliability.